In a significant move towards revitalizing the semiconductor industry, the U.S. Commerce Department has recently committed $406 million in grants to Taiwan’s GlobalWafers. This funding marks a crucial step in enhancing the production capabilities of silicon wafers in the United States. Designed to bolster domestic manufacturing, particularly in Texas and Missouri, this initiative is integral to the Biden administration’s broader strategy to foster self-sufficiency in semiconductor technology, which is increasingly deemed essential for national security and economic competitiveness.

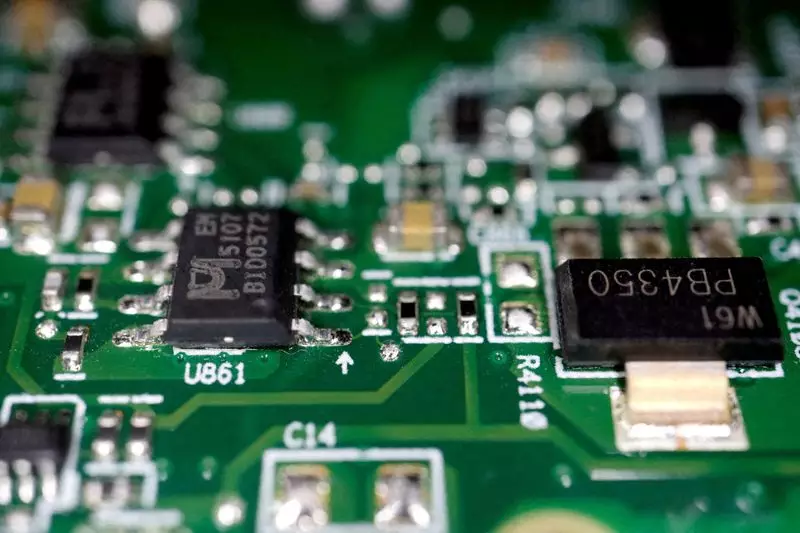

Silicon wafers serve as a fundamental building block in the production of semiconductors, influencing everything from consumer electronics to critical infrastructure technologies. The latest infusion of funds aims to facilitate the high-volume production of 300-mm wafers, a specification vital for advanced semiconductor applications. This initiative is commendable as the bulk of the global wafer manufacturing capacity currently resides in East Asia, leaving the U.S. susceptible to supply chain vulnerabilities.

GlobalWafers intends to establish manufacturing facilities that will not only meet current demands but also create jobs — estimating the generation of approximately 2,580 new positions in construction and manufacturing. This job creation is a critical facet of the initiative, as it promises to uplift local economies and foster a skilled workforce adept in semiconductor technologies.

In a strategic pivot, GlobalWafers changed its investment plans from Germany to the United States, detailing plans for a $5 billion plant in Texas. This maneuver reflects a growing trend among semiconductor manufacturers who are increasingly drawn to the favorable investment climate created by recent U.S. policies. The move away from reliance on foreign manufacturing not only strengthens domestic production capabilities but also serves to mitigate geopolitical risks associated with global supply chains.

The company’s proposed facilities in Sherman, Texas, and St. Peters, Missouri, will focus on different wafer types, including those used in advanced memory chips and defense applications. This diversification of production emphasizes the critical role semiconductors play in both civilian and military sectors, underscoring the importance of the U.S. semiconductor supply chain for national defense.

The urgency behind these initiatives is amplified by the CHIPS and Science Act, which allocated $52.7 billion for semiconductor manufacturing and research. The swift implementation of these grants underscores the U.S. government’s commitment to fortifying its semiconductor industry. Notably, other substantial subsidies awarded recently include $6.165 billion for Micron Technology and $7.86 billion for Intel, indicating a robust trajectory towards revitalization of domestic semiconductor manufacturing.

As the U.S. navigates its position in the global tech landscape, efforts to gain autonomy in semiconductor production symbolize a strategic move toward not only economic resilience but also technological leadership. In a time when digital innovations are at the forefront of global progress, investments like these are essential for sustaining growth and ensuring the country remains competitive.

The $406 million grant to GlobalWafers is more than a simple financial transaction; it represents a renewed commitment to transforming the U.S. semiconductor landscape. By enhancing production capabilities and fostering job growth, the U.S. is positioning itself to better respond to future challenges within the tech industry. It is evident that investments in domestic semiconductor manufacturing will lay the groundwork for innovation and, ultimately, ensure that the U.S. maintains a competitive edge in an increasingly interconnected global economy.